M600

Campus Marburg

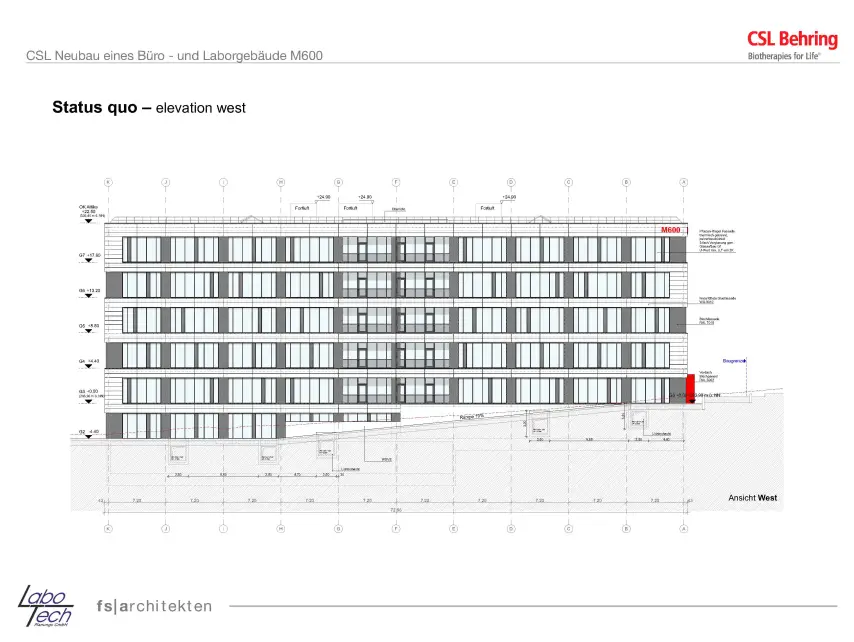

The office and laboratory building M600 was built on the Görzhäuser Hof factory site of CSL Behring GmbH in Marburg with Labotech as overall planner and general contractor. The office and laboratory areas are grouped around a five-story atrium. The atrium takes on the function of representative access and creates meeting areas for employees. The building brings together the R&D departments and offers a modern working environment for 600 employees.

The office concept offers employees the opportunity to flexibly choose the optimal workplace for their respective activities. The building contains different office zones. The zones differ in functionality, furniture, colour and materials. A unique and inspiring design was developed for all office areas.

Reference values

Laboratory zone

Research and development laboratories are subject to ever-increasing change. On the one hand, the focus of research is changing, and on the other hand, the work equipment used is changing (e.g. higher automation/robotics). In addition to restructuring the working groups, both always lead to adjustments within the laboratory zones. In order to carry out such conversions in the future without major disruption to adjacent areas and with little time and economic effort, there are high demands on the flexibility of the building structure and the technical building equipment.

The first priority is a large, connected laboratory area that can be planned flexibly. In the concept presented, there is a laboratory area of approx. 1,000m² per side of the building and floor. These are accessed through a central hallway which is required by building regulations, so that there are two connected laboratory areas of 500m² each. The laboratory area is bordered on both sides by shaft systems for supply/exhaust air, media and energy supply.

This ensures that the installations exit the shaft cleanly into the area. Ring connections for supply and exhaust air on both sides are provided, which means great flexibility in terms of air supply. The laboratory space provided for in the concept allows laboratory sizes of several 100m². The larger the connected laboratory areas can be, the easier it will be for later Remodeling, as only equipment and furniture need to be removed, replaced and connected to the building technology.

In areas with protection classes and levels according to GenTG and BioStoffV up to S2, it is recommended not to install suspended ceilings. This significantly simplifies subsequent installation, maintenance and servicing. The selected floor height of 4.40m and the resulting interior height of approx. 3.95m offers enough space for the installation of the technical equipment. This room height is also sufficient for very high installed areas, such as clean rooms and rooms with protection classes and levels up to S3. At 7.20m, the chosen axis grid is above the size required for laboratory buildings. This provides scope for larger-scale facilities and robotics applications. The building depth of the laboratory zone allows the arrangement of auxiliary laboratory rooms with high levels of noise and heat (refrigerator rooms, cold storage and freezer cells, etc.) indoors. There is the option of separate evaluation stations in the outside areas of the facades. There are four freight elevators on each floor, two assigned to each laboratory zone. Large storage areas for the laboratories can be found in the basements G1 and G2.